We travel further south and now take the coffee route in Colombia. Most of Colombia’s coffee-growing regions are located at an altitude of over 1,200 meters and are therefore suitable for Arabica coffee. But more on this in one of the next sections. Salento itself is a pretty little mountain village at an altitude of around 2,000m. The scenery never fails to fascinate us: palm trees grow in the main park in the center of Salento, even at this altitude. Behind them are cloudy hills and a good 20°C. The moderate climate suits us, but the fact that the palm trees are also doing well here is a bit of a mystery to us. There is probably no frost here, which would probably be fatal for the tropical backdrop in the city park.

Coffee tour with Luger

In the middle of Colombia’s coffee zone, we also treat ourselves to an immersion in the cultivation culture. We choose a small coffee farm about an hour’s walk outside Salento. On the way there, we are once again captivated by the warmth of the Colombian people. A car drives past us on the dirt road and then stops. Don’t you want a ride? Walking everywhere in Colombia is more of a must than a want – we accept the invitation and get to our coffee tour at Luger a lot quicker than expected.

The coffee tour is divided into three segments. First, we are taught the theoretical basics of good coffee. Then we become coffee farmers for half an hour and harvest the red coffee berries ourselves. Finally, we become coffee roasters and process our own coffee. To top it all off, we become coffee sommeliers for a small cup and taste the portion of coffee we have just made on the spot. So, let’s go through everything in a little more detail.

In contrast to the large coffee tour providers, Luger does not have groups of up to 40 people per tour. The two of us have our own guide and although other interested people arrive at the same time, they also get their own guide. Perfect for us – we like small groups much better as you really get to ask questions and hear everything the guide tells you. The fact that we can take part in and experience the whole process is another plus point and lastly, but perhaps almost the most important point; you really notice how enthusiastic our guide is about the coffee process and he transfers this enthusiasm fully into the tour. We haven’t been on such a great tour for a very long time!

Difference between Arabica and Robusta coffee

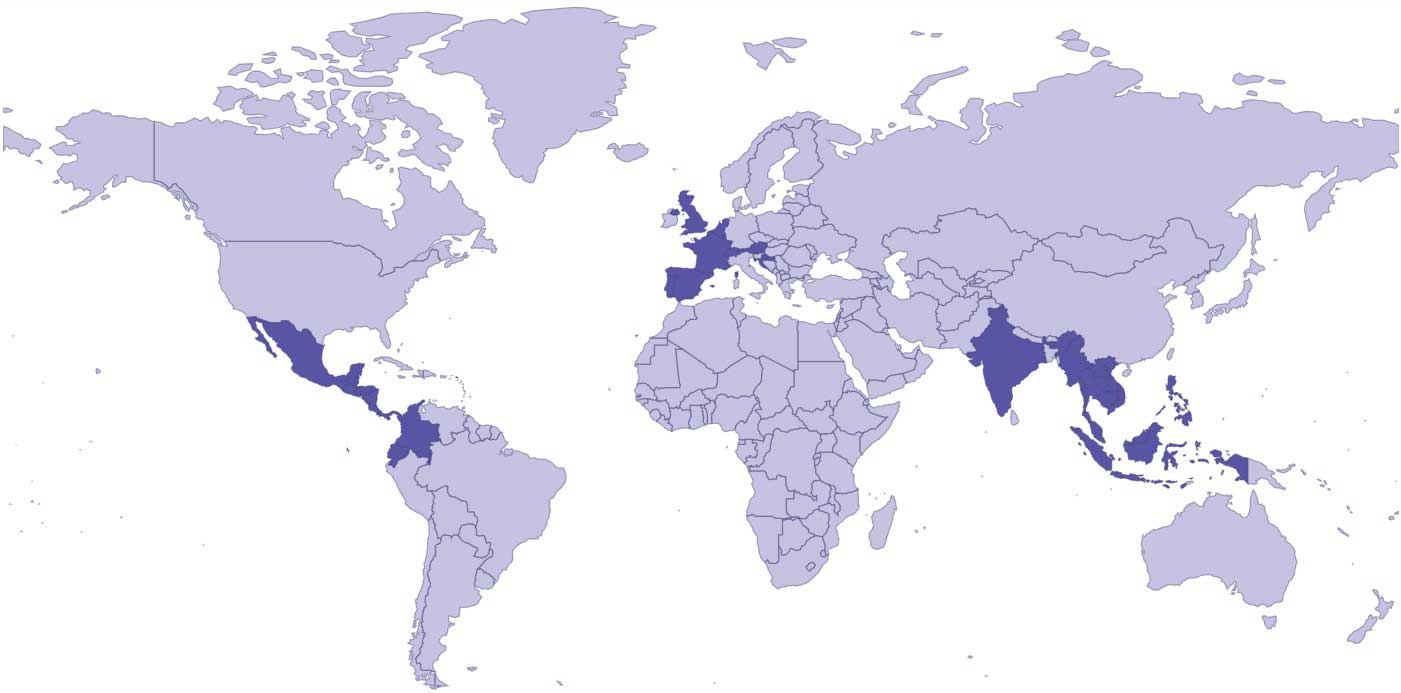

There are two main differences between the world-famous Arabica and Robusta coffee varieties. The most obvious is the taste. Robusta has many bitter notes on its own and therefore has a significant influence on the final taste of the coffee – whether in a blend or when Robusta coffee is used exclusively. The second important difference is the caffeine content of the coffee. Arabica coffee has much less caffeine. This is due to the different growing altitudes of the coffee. Arabica grows best between 1200m and 2400m altitude. At these altitudes, there are fewer insects to attack the plant and Arabica coffee produces less of its insect repellent caffeine. Robusta coffee, on the other hand, is not bound to a minimum altitude and grows best between sea level and around 1000m.

Accordingly, only Arabica coffee is grown at the Luger coffee farm due to the altitude of around 2000m. In addition, Arabica coffee has a more varied taste, as the subtle notes are not drowned out by the strong bitterness of Robusta. In addition, citrus fruits are cultivated next to the coffee plants in the coffee groves in order to allow citrus notes to flow into the final coffee. In general, the aroma of Arabica coffee is softer and fruitier than many coffees we have tried so far. However, the preparation process also plays an important role here; every stage of coffee production and preparation has a significant influence on the end result. High-quality coffee is therefore an Arabica coffee with many different flavors but no bitterness. The bitterness can still be added via the roasting or brewing process if required, but this is actually a shame as the many subtle flavors are lost in the process.

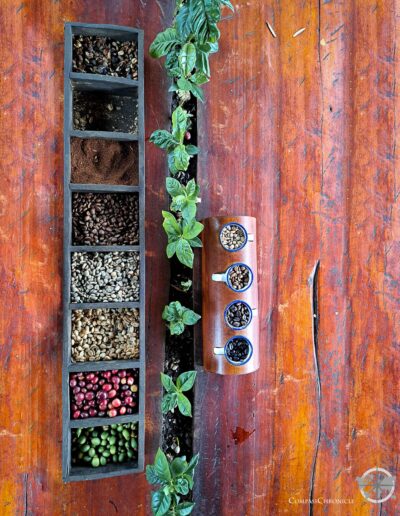

The steps of coffee production

The steps in coffee production are familiar. The coffee must first ripen until the coffee berries are red and ripe. They do not all ripen at the same rate and so the red berries have to be picked by hand from the coffee plant. The green berries are left alone, as they will also ripen at a later stage and early picking would mean a corresponding loss of harvest. The coffee beans are then pressed from the coffee fruit using the traditional method and washed in a basin of water. Washing not only serves to remove a small sugary film on the bean, but it also serves to separate the good beans from the bad ones. The beans attacked by insects float to the top and can be skimmed off before further processing.

Interesting fact: Colombia itself does not have a large coffee culture and the very light tinto is served at all times of the day. This is the typical Colombian coffee, which is served very cheaply on all street corners and sometimes in restaurants. However, it is actually a waste product from coffee production. The skimmed beans, which are not suitable for further quality processing, are nevertheless roasted to neutralize the insects and are then used to brew tinto. OK – so maybe it’s worth drinking one less tinto and one more real coffee in Colombia!

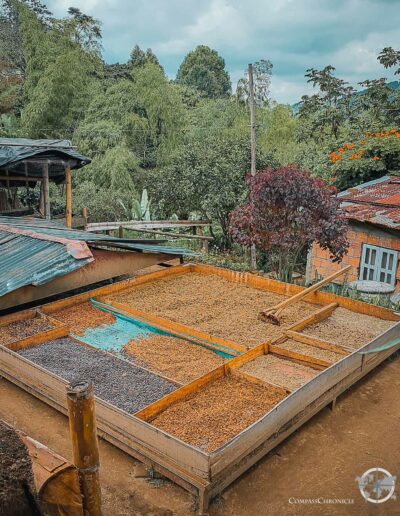

The good coffee beans are now dried to obtain the green coffee bean. The process is different. At the small Luger coffee farm, the beans are sun-dried. It takes many days, up to 8 months depending on the production process, to dry the beans. For regular coffee, drying takes about a month. After this, the bean is ready either for export or for further processing. Now the second skin of the coffee bean is removed and the roasting process begins. Finally, the bean is ground into coffee powder, which is then used to brew the coffee.

Harvest coffee yourself

After the theoretical introduction, we are kitted out with a hat, poncho and basket and become coffee farmers in true style. Our guide Alejandro takes us to the coffee plantation, where we pick our own coffee for the next few minutes. But be aware: only the red coffee berries should be picked! By the way, real coffee farmers and their employees do this work and are paid by the weight of their harvest. Many of these people work around 12 hours a day to pick around 150-200 kg of ripe coffee berries on a good day. There is probably no stopping them, the pay is so low that they have to continue working in all weathers and every day in order to earn a sustainable income for the family.

After the harvest, the coffee is processed by a mechanical machine that separates the coffee bean from the outer shell. We have already been able to experience this process in a somewhat more extensive form in San Pedro, Guatemala, at our Spanish school. From there, the beans fall directly into the water bath to be washed and subjected to quality control as described above.

Roasting coffee

We can casually look at the drying bed of coffee beans. Of course, we don’t have at least four weeks to watch the beans dry. Instead, we now roast two handfuls of coffee from other tourist collectors together with Alejandro. First, the fine second skin is removed from the coffee beans. Then the green coffee bean is roasted in an iron pan over a gas flame on a normal hob without any great technical effort. The only thing: constant stirring is extremely important in order to achieve an even result. The speed impresses us. It only takes around seven minutes to roast the two handfuls of beans to a medium roast. The change in color of the coffee beans is just as exciting. The green bean soon turns quite yellow. This would be the first possible roast level, such a coffee has little to no bitter notes. Gradually, the coffee beans then turn bronze and finally chocolate brown. This is a medium roast and we want to preserve the natural aromas of the coffee paired with a slight bitterness. The coffee beans are removed from the flame and cooled slightly with cold air so that the beans do not continue to roast. Our own coffee is ready!

Taste coffee from our own production

Now comes the best part of the whole production process. We grind the fresh coffee and get to taste the coffee that has just been roasted. Luger does not use a fancy brewing process, simply pour hot – but not boiling! – water in a cotton bag and our coffee is ready. Amazing! This coffee has almost nothing to do with the European quality standard of Italian coffee, but it is still good in its own way. Alejandro is fond of the opinion that this Italian way of brewing coffee has two disadvantages. Firstly, under high pressure and high temperature, the bitter substances are overemphasized. Secondly, the coffees are often roasted very dark or too dark, so that the quality is ultimately minimized again with the over-roasting.

Colombians can drink their tinto or a coffee like the one we brewed ourselves all day long. It is not uncommon to drink 10 to 20 cups without suffering any impairment of well-being. The strong Italian coffee with lots of caffeine and bitter substances, on the other hand, would also only be tolerated by our guide Alejandro for a few cups a day. So, he concludes for himself and probably for the whole of Colombia that their simple brewing method is probably better and more tolerable.

We are divided, because there is something to be said for a thick, almost chocolatey Italian espresso. Nevertheless, we have to agree with Alejandro that the Colombian brewing method brings out the very fine aromas better.

And finally, we almost forget to hand back our poncho and hat, we could stay at the coffee farm for a while – the tour was fun and Alejandro was more than motivated to offer us an impressive coffee experience. Anytime again with pleasure!

0 Comments